Isku xirka Kursiga go'an ee gacan-gacmeedka giraanta go'an ee tiirka furka fiilada aluminiumka

Halbeegyada

| Mashiinka CNC ama maya | Cnc Machining | Dulqaad | ± 0.005-0.01 | ||

| Awoodaha Qalabka | Aluminium, Naxaas, Bronze, Copper, Biraha Adag, Biraha Qaaliga ah, Birta Dahsoon, Alloysyada Birta | Baakad | Bacaha PP/PE ee ka hortagga miridhku xumbo Sanduuqyada kartoonnada Saqafka alwaaxyada | ||

| Nooca | Wareejinta, Qodista, Etching / Mashiinka Kiimikada, Mashiinka Laser-ka, Milling, Adeegyada Mashiinka Kale | Alaabta la heli karo | Aluminium, copper, birta, birta, aluminium titanium, POM, ABS, naylon | ||

| Micro Machining ama maya | Micro Machining | Logo | Aqbal astaanta gaarka ah | ||

| Nambarka Model | Aluminium cs113 | Shahaado | ISO 9001:2015 | ||

| Magaca Summada | OEM | Codsiga | Qalabka otomaatiga ah | ||

| Nooca Habaynta | Milling Turning Machining Casting Stamping | Dhamaystirka | polishing anodizing | ||

| Tusaale | 7 maalmood gudahood | ||||

| Waqtiga hogaaminta: Qadarka wakhtiga laga bilaabo meelaynta dalbashada ilaa diritaanka | Tirada (qaybo) | 1-10 | 11-100 | 101-1000 | > 1000 |

| Waqtiga hogaaminta (maalmo) | 5 | 7 | 17 | In laga wadahadlo | |

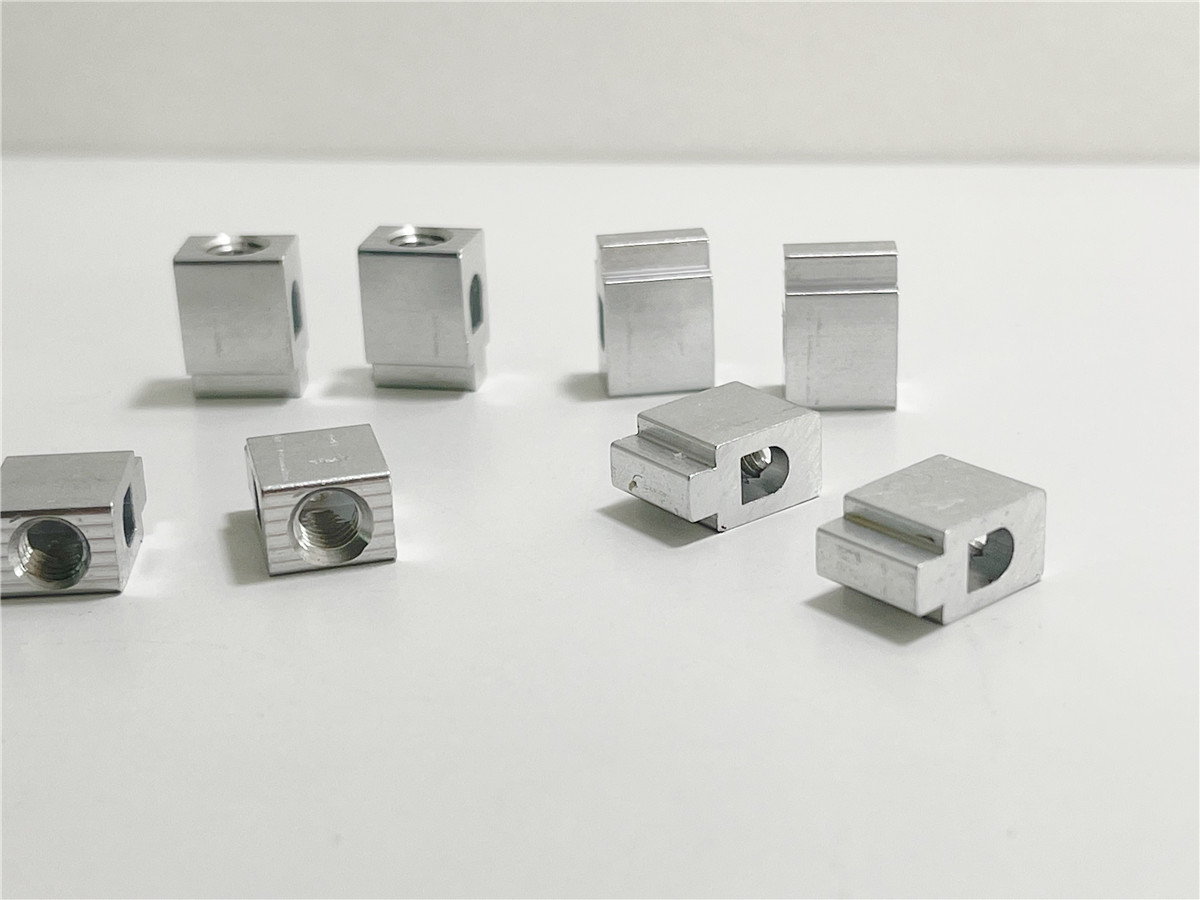

Faahfaahinta Alaabta

1. Qaybaha Birta Saxda ah ee Sare

Xidhiidhiyaha aluminiumku waa qayb bir ah oo sax ah, taas oo inta badan laga sameeyay alaab tayo sare leh oo aluminium ah oo sax ah oo lagu farsameeyo farsamada farsamada ee CNC. Habka wax-soo-saarka ee qaybtani waxay u baahan tahay isticmaalka qalabka sare ee CNC ee qalabka wax lagu dhejiyo iyo farsamada farsamaynta dhidibo badan si loo hubiyo saxnaanta iyo qaabka qaabka.

2. Shaqada ugu weyn: isku xidh qaybaha ama qaybaha kala duwan

Shaqada ugu weyn ee qaybtan waa in la isku xiro xubnaha ama qaybaha kala duwan oo la isku xiro. Caadi ahaan waxa uu ka kooban yahay kursi isku xidha, qoor go'an, tiir go'an iyo xajin. Socket-ku wuxuu bixiyaa madal lagu dhejin karo qaybaha kale. Shaqada koodhka go'an iyo boostada go'an waa in la hubiyo xasilloonida iyo isku halaynta isku xirka iyada oo la ilaalinayo xad-dhaaf ah iyo cidhiidhi. Isku-xidhka isku-xidhka waxa loo isticmaalaa in lagu xidho xidhiidhiyaha oo dhan si loo hubiyo xidhiidh adag.

3. Faa'iidooyinka habka farsamaynta CNC

Xidhiidhiyaha aluminiumka oo leh gacmo go'an, giraan, fur tiir go'an iyo isku xirka aluminium ee ay samaysay tignoolajiyada farsamaynta CNC ayaa leh faa'iidooyin badan. Ugu horreyntii, habka farsamaynta CNC wuxuu leeyahay saxnaanta sare iyo xasilloonida, taas oo hubin karta saxnaanta iyo joogtaynta cabbirka qaybta. Sidan oo kale, xiriiriyuhu wuxuu si fiican ula qabsan karaa shuruudaha isku xirka kala duwan wuxuuna hubin karaa cidhiidhiga iyo xasilloonida xiriirka.

4. Waxay bixisaa xulashada shakhsi ahaaneed iyo xalalka hagaajinta

Habka rogid iyo habaynta caadada ee kursiga isku xirka, hagaajinta sleeve, tiir go'an oo isku dhejinta aluminium isku xiraha waxay siisaa macaamiisha xulashooyin shaqsiyeed iyo xalal hagaajin. Macaamiishu waxay habayn karaan isku xidhayaasha cabbirro kala duwan, qaabab iyo hawlo kala duwan iyadoo loo eegayo baahiyahooda iyo baahidooda. Isla mar ahaantaana, kooxdayada xirfadlayaasha ah ayaa bixin doona taageero farsamo iyo talo si loo hubiyo natiijooyinka ugu fiican ee naqshadeynta iyo habaynta isku xirka.