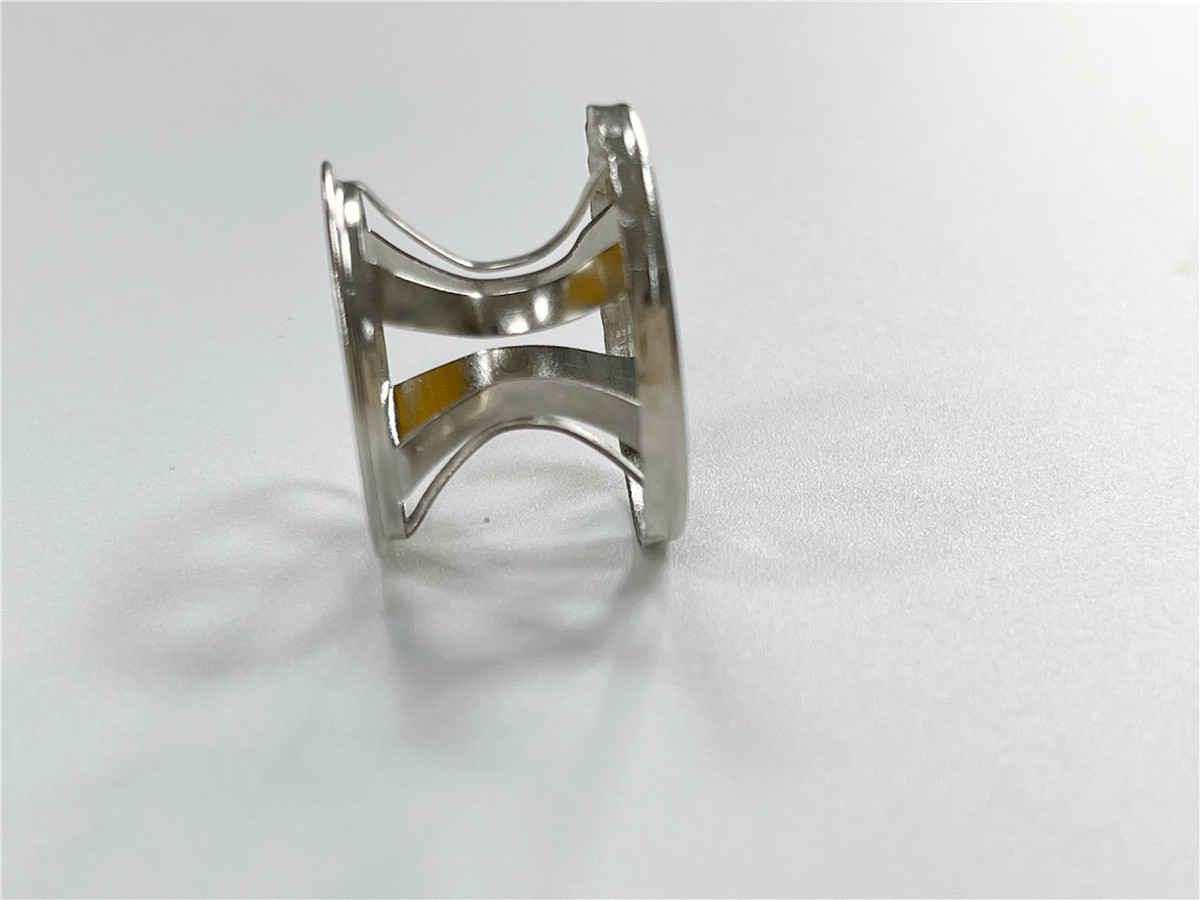

Ku Shaabadeynta Qaybaha Birta Aan-Aamiga ahayn

Halbeegyada

| Mashiinka CNC ama maya | Cnc Machining | Dulqaad | ± 0.005-0.01 | ||

| Awoodaha Qalabka | Aluminium, Naxaas, Bronze, Copper, Biraha Adag, Biraha Qaaliga ah, Birta Aanay Lahayn, Alloys Birta, titanium | Baakad | Bacaha PP/PE ee ka hortagga miridhku xumbo Sanduuqyada kartoonnada Saqafka alwaaxyada | ||

| Nooca | Wareejinta, Qodista, Etching / Mashiinka Kiimikada, Mashiinka Laser-ka, Milling, Adeegyada Mashiinka Kale | Alaabta la heli karo | Aluminium, copper, birta, birta, aluminium titanium, POM, ABS, naylon | ||

| Micro Machining ama maya | Micro Machining | Logo | Aqbal astaanta gaarka ah | ||

| Nambarka Model | ST013 | Shahaado | ISO 9001:2015 | ||

| Magaca Summada | DGCS | Codsiga | Qalabka otomaatiga ah | ||

| Nooca Habaynta | Milling Turning Machining Casting Stamping | Dhamaystirka | polishing anodizing | ||

| Tusaale | 7 maalmood gudahood | Qalab | bir caag bir ah | ||

| Waqtiga hogaaminta: Qadarka wakhtiga laga bilaabo meelaynta dalbashada ilaa diritaanka | Tirada (qaybo) | 1-10 | 11-100 | 101-1000 | > 1000 |

| Waqtiga hogaaminta (maalmo) | 5 | 7 | 17 | In laga wadahadlo | |

Faahfaahinta Alaabta

1. Tiknoolajiyada farsamaynta xirfadlaha ah ee CNC

First of dhan, wax soo saarka ee qaybaha birta ahama ahama shaabadeeyey qaatay technology processing CNC xirfadeed. Farsamadan makiinadu waxay u oggolaanaysaa in si sax ah loo xakameeyo tallaabo kasta oo hawlgal ah, iyada oo hubinaysa saxnaanta cabbirka ee qaybta. Saxnimada sare iyo xasiloonida qalabka farsamaynta ee CNC waxay ka dhigaysaa habka farsamaynta ee ku shaabadeynta qaybaha birta ah ee birta ah mid hufan oo la isku halayn karo, waxayna buuxin kartaa shuruudaha adag ee macaamiisha si sax ah.

2. Hubinta saxnaanta adag

Marka labaad, qaybaha birta ah ee sida caadiga ah loo shaabadeeyay ayaa mara baadhitaano sax ah oo adag. Inta lagu jiro habka farsamaynta, qaybtu waxay martaa kormeero sax ah oo badan si loo hubiyo inay buuxisay shuruudaha macaamiisha. Qaybaha ka gudba jeegaga saxda ah ayaa loo qaadan karaa alaab tayo leh. Hubinta saxda ah waxay bixisaa hubinta ugu badan ee tayada iyo xasiloonida qaybta.

3. Faa'iidooyinka adeegyada gaarka ah

Intaa waxaa dheer, faa'iidooyinka adeegyada gaarka ah ee qaybaha birta ah ee aan shaambada lahayn ayaa sidoo kale ka muuqda adeegyada kala duwan ee ay bixiso. Inta lagu jiro nidaamka habaynta, waxaan si dhow ula shaqaynaa macaamiisheena si aan u fahanno baahiyahooda gaarka ah iyo shuruudaha. Kooxdayada xirfadlayaasha ah ayaa siin doona macaamiisha la-talinta shakhsi ahaaneed iyo soo jeedinta naqshadeynta, oo ay samayn doonaan wax ka beddel iyo hagaajin ku salaysan jawaab-celinta macaamiisha ilaa waxa macmiilku ka filayo. Ma bixinno oo kaliya wax soo saarka qaybo tayo sare leh, laakiin sidoo kale waxaan bixinaa bixinta wakhtiga iyo adeegga iibka ka dib si loo hubiyo qanacsanaanta macaamiisha iyo kalsoonida.

Marka la soo koobo, wax ka beddelka qaybaha birta ah ee birta ah ee ay sameeyeen xirfadlayaasha CNC mashiinnada saxda ah ee saxda ah iyo shaabadeynta ayaa leh faa'iidooyin badan. Ma laha oo kaliya tignoolajiyada farsamaynta saxda ah oo degan, laakiin sidoo kale kormeer sax ah oo adag iyo adeegyo dhamaystiran ayaa ka dhigaya doorasho ku habboon dhammaan qaybaha nolosha. Waxaa naga go'an inaan siino macaamiisha qaybo tayo sare leh oo wax soo saar leh iyo khibrad adeeg oo ku qanacsan si aan u buuxinno shuruudaha macaamiisha ee tayada iyo waxqabadka.